Check what we can offer you

Timely implementation

We perform all the tasks entrusted to us in accordance with the agreed deadline.

Distance is not a problem

We carry out orders all over Poland and abroad.

Quality control

Before being released, each product undergoes a thorough quality control.

LASER SHEET CUTTING

Laser cut

We use a Bystronic BySmart Fiber 3015 laser cutting machine.

It allows for a wide range of applications, where, in addition to “black” steel, stainless steel and aluminum, we also have the ability to process non-ferrous metals with the highest quality.

We are able to ensure 100% repeatability of dimensions while maintaining continuous and uninterrupted production and the highest quality.

We perform laser cutting on various types of metal sheets with a maximum sheet size of 3000 × 1500 mm.

The maximum thickness of the sheets may not exceed:

| Steel | 25 mm |

|---|---|

| Stainless steel | 30 mm |

| Aluminum | 30 mm |

| Brass | 15 mm |

| Copper | 12 mm |

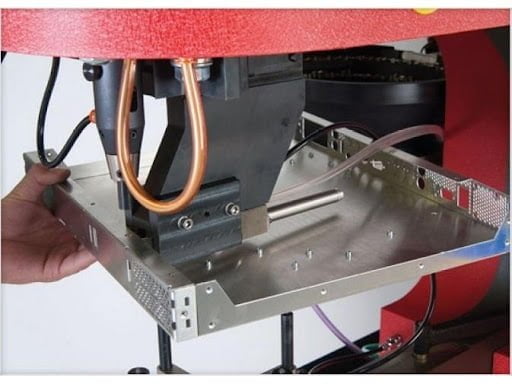

SHEET EDGING

Sheet bending

We offer the highest quality sheet metal bending services using a modern CNC press brake SAFAN H-Brake 170-3100.

By using a numerically controlled press, we are able to obtain high precision and, at the same time, a minimum risk of error, thus maintaining the tolerance range of the linear and angular dimensions of the bending. This guarantees the serial repeatability of the manufactured elements.

Thanks to the SAFAN press brake, we have the ability to form many curves in order to obtain very complex shapes, with the simultaneous lack of imperfections of the processed material.

Technical data of the press brake

| Pressure | 170 T |

|---|---|

| Bending length | 3100 mm |

| Max. jump | 290 mm |

PROTECTION OF THE SURFACE

Powder Painting

By using our offer, we provide professional advice regarding the selection of paints, possible finishes and effects. We will select the appropriate type of surface protection, taking into account its purpose and the impact of weather conditions in such a way that the surface looks good for years.

We place great emphasis on making each stage of painting carried out with the utmost care and with the standards that we follow. Our employees are experienced varnishers who take care of the quality during every stage of work.

We guarantee the durability of coatings and the highest level of painting aesthetics.

CONNECTING ELEMENTS

Pemming

We perform the processes of setting assembly joints on the hydraulic computer-aided device HAEGER 618 MSPe

Thanks to the use of the latest techniques and devices, and with the help of qualified employees, it is possible to effectively perform orders that require permanent joining of elements.

The benefits of pemowanie include: possibility of fast cold mounting and increasing the speed of work.

We offer insertion of all kinds of push-in connectors:

| Self-clinching nuts |

| Ring fittings |

| Threaded studs |

| Self-clinching panel fasteners |

| Pins without thread |

| Combined screws |

| Through and blind threaded bushes |

Order Processing Stages

Consultation with the client

We talk with the client and propose optimal solutions in order to make the best quality product. The customer can present his project or, if necessary, we create the appropriate file from scratch.

Execution of the contract

Modern machines and a team of professionals allow for comprehensive service of even the most advanced orders. All in a relatively short time.

Inspection and Delivery

Before delivering the finished product to the customer, we conduct quality checks to guarantee customer satisfaction with the order. After agreement, we can deliver the finished product to the address indicated.